Технології та інновації - це про нас!

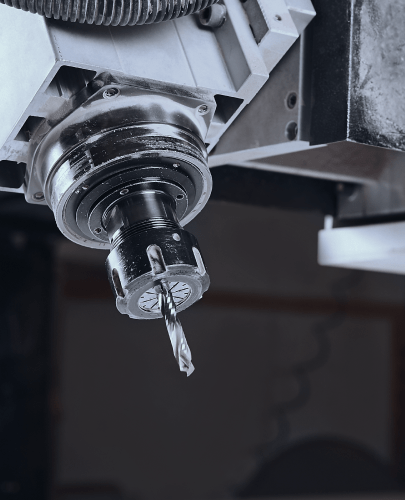

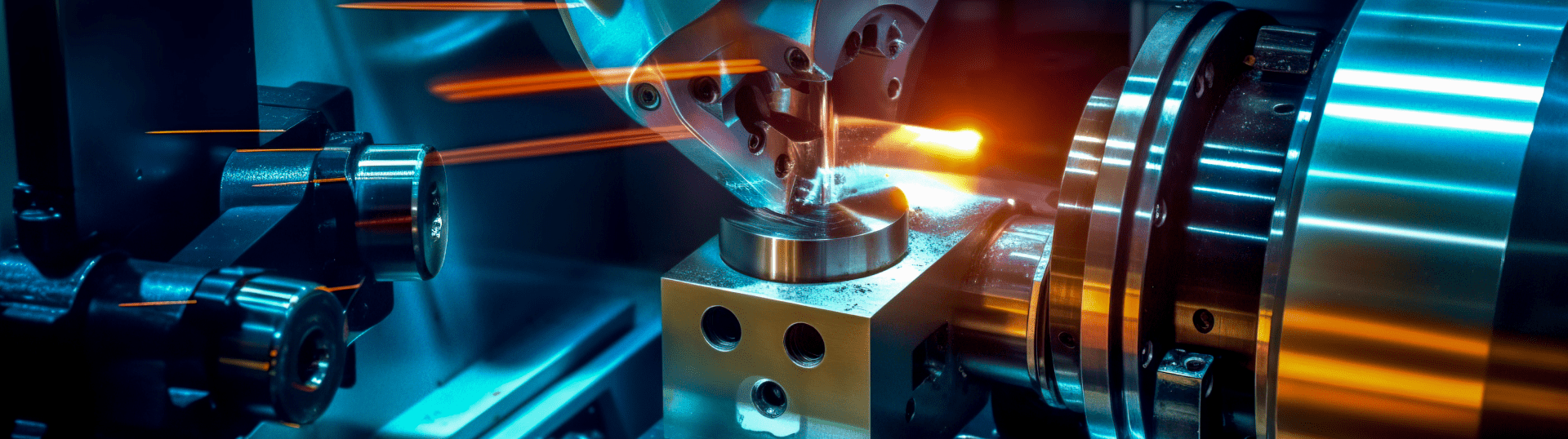

Український виробник обладнання з ЧПУ

Тисячі задоволених клієнтів в Україні та за кордоном

Якісне обладнання з ЧПУ від виробника

Історія компанії «ІнСтанкоСервіс» розпочалася у 2003 році. Саме тоді ще невеликий колектив зайнявся проектуванням та виробництвом перших моделей верстатів з ЧПУ серії ATS. І вже у 2004 році на київській міжнародній виставці «Lisderevmash-2004» було представлено серійну модель верстата ATS-2112.

За роки своєї діяльності компанія «ІнСтанкоСервіс» виробила понад дві тисячі одиниць обладнання з ЧПУ, високу якість та надійність якого оцінили не тільки в Україні, а і в різних куточках світу: Молдові, Польщі, Ізраїлі, Іспанії, Чехії, США.

Років існування компанії

Вироблено одиниць обладнання

Моделей верстатів з ЧПУ

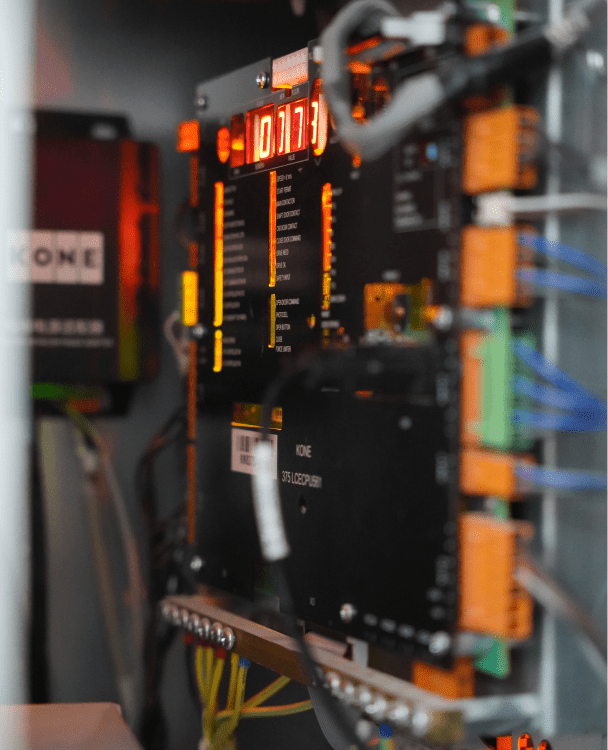

Наше обладнання, побудоване на базі сучасних рішень і поєднує в собі високі показники надійності, ефективності та безвідмовності в роботі

Двадцять років успішної роботи в галузі верстатобудування. Завдяки надійності та високій якості, наші верстати знайшли визнання в Україні та за кордоном

Якісні комплектуючі, підбір обладнання під Ваші потреби, консультація та технічна підтримка впродовж всього терміну експлуатації обладнання

Пропонуємо готові до роботи верстати з ЧПУ, пусконалагоджувальні роботи, найкращі умови навчання, один рік гарантії та сервісне обслуговування

Верстати з ЧПУ є невід’ємною складовою сучасних виробничих технологій і сприяють підвищенню продуктивності та якості в різних галузях промисловості і зменшенню витрат на виробництві.

Застосування верстатів з ЧПУ відкриває нові можливості виробництва, дозволяючи виготовляти складні деталі та вироби з високою точністю, швидкістю і повторюваністю, що є важливим для забезпечення якості продукції.

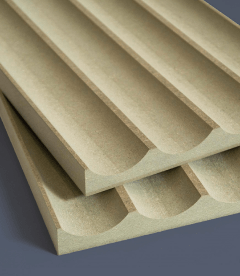

Верстати з ЧПУ використовуються в різних сферах виробництва, включаючи: деревообробку, виготовлення меблів та кухонних фасадів, зовнішню рекламу, сувенірну продукцію, моделебудування, дизайн та архітектуру та багато іншого.

Верстати ЧПУ вже давно стали важливим інструментом розвитку бізнесу, забезпечуючи компаніям можливість оптимізувати виробничі процеси та підвищувати ефективність виробництва. На сьогоднішній день, вибір правильного верстата з ЧПУ стає ключовим завданням для підприємств, оскільки від цього залежить якість виробництва та конкурентоспроможність на ринку.

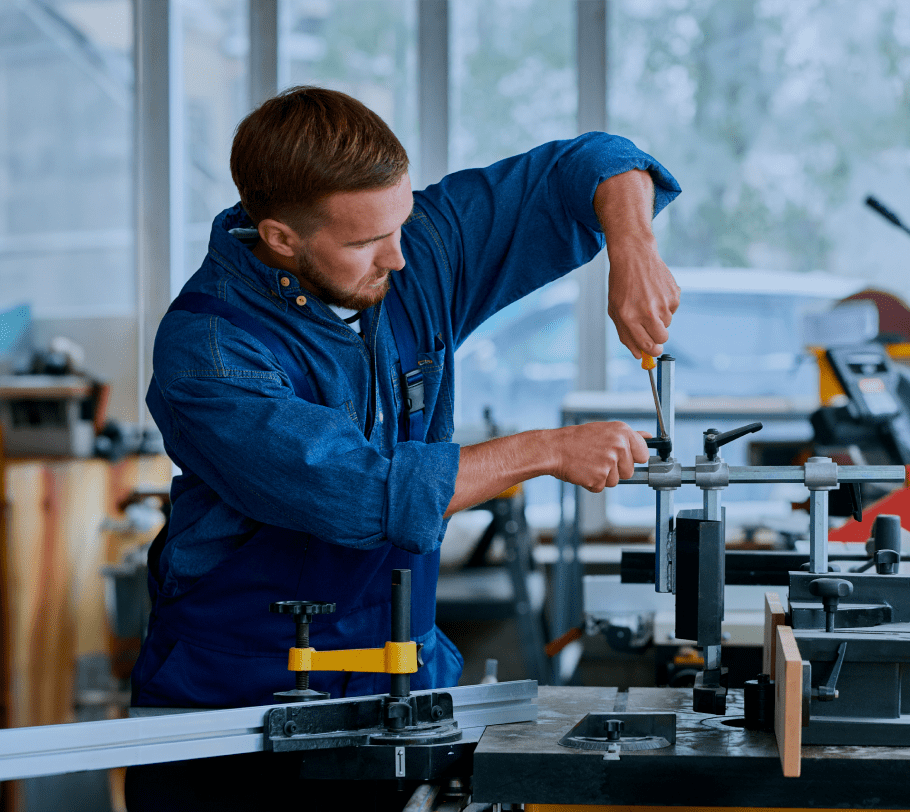

Коли стає питання купити верстат з ЧПУ, важливо розуміти потреби виробництва та технічні вимоги, щоб зробити правильний вибір оптимальної моделі. Компанія Інстанкосервіс має двадцятирічний досвід в сфері верстатобудування. Ми спеціалізуємося на наданні рішень, які відповідають потребам сучасного виробництва, а наша експертність і підходи підкреслюються високою якістю послуг та глибоким розумінням потреб сучасного бізнесу. Ми не тільки готові підібрати верстати з ЧПУ, а й надати повний спектр підтримки і консультацій, щоб стати надійними партнерами в довгостоковій перспективі.

Наш асортимент налічує понад 30 моделей верстатів з ЧПУ, за допомогою яких можлива реалізація будь-яких задач, пов’язаних з такими видами діяльності як:

Наші верстати з ЧПУ працюють на провідних виробництвах в Україні та закордоном і забезпечують високу точність обробки, ефективність виробництва та можливість реалізації складних проектів у різних галузях промисловості. Багаторічна співпраця дозволила нам сформувати базу постійних клієнтів, бізнес яких побудований на обладнанні нашого виробництва.

Виготовимо та доставимо верстати по Україні та закордон, надамо індивідуальні рішення, консультації та підтримку на кожному етапі використання обладнання.